How to calculate polydispersity index of polymer?

Therefore, PDI = Mw/Mn = 60,000/40,000 = 1.5 (>1). The polymer with the value (>1) have monomer units arranged in chains of different length. Mw/Mn>1⇒ Mw>Mn ⇒ most probably it is a natural polymer. When the PDI value is one, it indicates mono dispersity or given polymer has monomers arranged in chains of equal length.

How to calculate PDI in DLS?

The pdi for that peak is the square of the standard deviation divided by the square of the mean. As an example consider the peak was at a mean size of 9.3nm and the st dev was 4.4nm. As a result then the pdi for this peak would be: 4.4*4.4/(9.3*9.3) = 0.22.

How is polydispersity measured?

The polydispersity index corresponds to the ratio of the molar mass by weight to the molar mass by number. The polydispersity index can be measured with instruments using dynamic light scattering (DLS).

What is the PDI range of polymers?

Man-made polymers are always polydisperse particles. The best controlled synthetic polymers (narrow polymers used for calibrations) have PDI of 1.02 to 1.10. Step polymerization reactions typically yield values of PDI of around 2.0, whereas chain reactions yield PDI values between 1.5 and 20.

How do you calculate polydispersity index PDI?

PDI (Polydispersity Index), defined by PDI=µ2/Γ , which indicates the width of the distribution. As a rule of thumb, the following PDIs are shown for different samples. DLS is a technique suitable for samples whose particle size distributions are relatively narrow.

What is a good PDI value?

PDI value that is range from 0.1 to 0.25 suggests that the size distribution is narrow, but if this value bigger than 0.5 it shows a very broad distribution. If a scientist wanted to achieve long-term stability, it is important to arrange the PDI parameter to be as low as possible (Yeo, 2013).

What is PDI calculation?

PDI of a polymer is calculated as the ratio of weight average by number average molecular weight.

What is a good PDI for DLS?

The value of Polydispersity Index may vary from 0.01 (mono dispersed particles) to 0.5-0.7, whereas, PDI Index value > 0.7 indicated broad particle size distribution of the formulation. The particle size and particle size distribution are very critical factors for performance evaluation of nanoparticles.

What is %PD in DLS?

Polydispersity. In light scattering, the term polydispersity and % polydispersity are derived from the Polydispersity Index, a parameter calculated from a Cumulants analysis of the DLS-measured intensity autocorrelation function.

Why is the polydispersity index always greater than 1?

In natural polymers, which are generally monodispersed, PDI is 1 and in synthetic polymers which are always polydispersed, PDI is greater than 1 because M¯w is always higher than M¯n. The PDI (polydisersity index) is the ratio of weight to number-average molecular masses, M¯w/M¯n.

What is the limit of polydispersity index?

A PDI value of 1 indicates that the sample has a very broad size distribution and may contain large particles or aggregates that could be slowly sedimenting. PDI always is below 1 . for biologic polymers it may be 0.4-0.7. right value for these system is 0.4.

What is the polydispersity index of a natural polymer?

For natural polymers, PDI (Polydispersity Index) is generally equal to 1, which means that they are monodisperse. Such polymers are more homogeneous.

What is the normal value of PDI?

The range of PDI values is 0-0.05 for the monodisperse system,0.05-0.08 for nearly monodisperse, 0.08-0.7 for that of midrange polydisperse, and >0.7 is a very polydisperse sample.

How to reduce polydispersity index?

PDI polymer micelles can be reduced by adding an inorganic electrolyte. The PDI of the molar mass must be measured before the formation of micelles, and the PDI of micelles after the critical concentration of micelle formation.

Which polymer has PDI value 1?

When PDI value is one, it indicates the monodispersity or given polymer has monomers arranged in chains of equal length. Synthetic polymers are usually less homogeneous and so their PDI is greater than 1. So, in the given option, cellulose is a natural polymer, hence its ODI poly disparity index is equal to $1$.

How is the polydispersity index measured?

Basic Idea Behind PDI Their mean data are divided into two categories: the average molar mass of the molecule and the weight-average molar mass of the particle. The Poly Dispersity Index is measured as the proportion of these average numbers.

What is the PDI a measure of?

In the field of polymer science, PDI is employed to measure the breadth of the molecular weight distribution (MWD) of the polymer. PDI can be defined as Mw/Mn, where Mw is the weight average and Mn is the number average molecular weight [80,81].

What is the formula of PDI in chemistry?

It is always greater than 1, Polymers with PDI greater than 1 can be synthesized. The P(poly) Dispersity Index (PDI) of a polymer is: (¯¯¯¯¯¯¯¯Mw= weight average molecular mass and ¯¯¯¯¯¯¯¯Mn= number average molecular mass).

Is a PDI of 0.1 good?

Which PDI values are considered good? A PDI value of ≤ 0.1 is considered a highly monodisperse sample; PDIs up to 0.3 are considered mostly monodisperse; a PDI from 0.3 to 0.7 is somewhat polydisperse; and a PDI > 0.7 is considered highly polydisperse and unsuitable for DLS.

What is the PDI percentage?

PDI = weigh of the pellet after tumbling / weight of Pellet before tumbling x 100. At PDI lower than 85 pellet tends to break during crumbling; producing more fines which result in more recycling of feed and low final output.

What is the best PDI?

However, in general, a PDI value closer to 0 is often considered to be better for most applications.

What is polymer PDI?

The Polydispersity Index (PDI) is a measure of the distribution of molecular mass in a given polymer sample. It provides an idea about the spread of molecular weight in a polymer distribution. It is numerically equal to the weight-average molecular weight divided by the number-average molecular weight.

What is PDI in manufacturing?

A pre-delivery inspection (PDI) is a kind of vivid inspection, carried out by the Quality Check (QC) Inspector, prior to the final delivery of the manufactured product.

What is the meaning of PDI index?

The power-distance index (PDI) is a measurement of the acceptance of a hierarchy of power and wealth by the individuals who make up the general population of a nation, culture, or business.

Why is low PDI good?

A low polydispersity index (PDI) in materials science refers to a narrow distribution of molecular weights within a polymer, indicating uniformity in chain lengths. This characteristic is crucial as it leads to consistent material properties, such as mechanical strength and structural integrity.

What is polydispersity in DLS?

The term polydispersity (or more recently dispersity without the poly, as per IUPAC recommendation) is used to describe the degree of “non-uniformity” of a distribution.

What is the ISO standard for DLS?

ISO 13321, photon correlation spectroscopy, was developed in 1996. A general standard for DLS (ISO 22412) was developed in 2008 . The current edition of ISO 22412 is a combination of ISO 13321 and the first edition of ISO 22412. Several methods have been developed for DLS.

What is the PDI ratio?

The PDI (polydisersity index) is the ratio of weight to number-average molecular masses, M¯w/M¯n. In natural polymers, which are generally monodispersed, PDI is 1 and in synthetic polymers which are always polydispersed, PDI is greater than 1 because M¯w is always higher than M¯n.

What is the polydispersity index value?

PDI is basically a representation of the distribution of size populations within a given sample. The numerical value of PDI ranges from 0.0 (for a perfectly uniform sample with respect to the particle size) to 1.0 (for a highly polydisperse sample with multiple particle size populations).

What is the PDI value of natural polymers?

For natural polymers, PDI (Polydispersity Index) is generally equal to 1, which means that they are monodisperse.

What is the polydispersity index of PLA?

The PLA polydispersity index (PDI) value of 2.23 is evidence of a broad molecular weight distribution. A typical polymer PDI is 1 to 3: three being much dispersed and one being mono dispersed.

How do you calculate polydispersity index of a polymer?

What is a polydispersity index (PDI)?

Do molecular weight distributions have a unique polydispersity index?

How do you calculate poly dispersity index (PDI)?

Hey there, polymer enthusiasts! Today we’re going to dive into the world of polydispersity index (PDI), a crucial characteristic for understanding the properties of polymers.

Think of it this way: You’re baking a cake and you want it to be perfectly fluffy. If you use flour with different particle sizes, you might end up with a cake that’s uneven and lumpy. Similarly, polymers with different chain lengths can lead to a variation in their properties.

Polydispersity is the term used to describe this variation in chain lengths within a polymer sample. The polydispersity index (PDI) is a numerical measure of this variation.

Let’s break it down:

What is a polymer?

Before we get into the nitty-gritty of PDI, let’s refresh our understanding of polymers. Polymers are large molecules made up of repeating structural units called monomers. Think of them like long chains made of smaller, identical building blocks.

Examples of Polymers:

Polyethylene (PE): Used for plastic bags, bottles, and films.

Polypropylene (PP): Used for packaging, fibers, and containers.

Polyvinyl chloride (PVC): Used for pipes, windows, and flooring.

Polystyrene (PS): Used for cups, plates, and insulation.

Why is Polydispersity Important?

Knowing the PDI of a polymer is vital because it directly impacts its physical and mechanical properties:

Strength: A polymer with a narrow PDI (meaning the chain lengths are more uniform) tends to be stronger and more durable.

Viscosity: Polymers with higher PDIs generally have higher viscosities, making them less easy to process and handle.

Solubility: The PDI can influence a polymer’s solubility in different solvents.

Calculating the Polydispersity Index

The PDI is calculated by dividing the weight-average molecular weight (Mw) by the number-average molecular weight (Mn).

Here’s the formula:

PDI = Mw / Mn

Let’s unpack these terms:

Number-average molecular weight (Mn): This is the average molecular weight of the polymer chains calculated by considering the number of molecules. It’s like taking the average age of a group of people.

Weight-average molecular weight (Mw): This is the average molecular weight calculated considering the weight of each molecule. Think of it like calculating the average weight of a group of people based on their individual weights.

Methods to Determine Molecular Weights:

Several techniques are used to determine the molecular weights of polymers and consequently the PDI. Here are a few:

1. Gel Permeation Chromatography (GPC): This technique separates polymer chains based on their size. The larger chains elute first, followed by the smaller chains. The peak area in the chromatogram can be used to determine the average molecular weights.

2. Light Scattering Techniques: These techniques measure the scattering of light by polymer molecules. The scattered light intensity can be used to determine the molecular weight and PDI.

3. Viscometry: This technique measures the viscosity of a polymer solution. The viscosity is related to the molecular weight of the polymer.

Interpreting the Polydispersity Index

PDI = 1: This indicates a monodisperse polymer, meaning all chains have the same length. This is rarely achievable in practice.

PDI > 1: This indicates a polydisperse polymer, meaning the chains have a range of lengths. The higher the PDI, the wider the distribution of chain lengths.

Factors Affecting Polydispersity

The PDI of a polymer can be influenced by several factors:

Polymerization Mechanism: Different polymerization mechanisms can lead to different PDI values.

Reaction Conditions: Temperature, concentration, and catalyst type can all affect PDI.

Post-polymerization Processes: Processing techniques like extrusion and molding can alter the PDI of a polymer.

Importance of PDI Control

Controlling the PDI is essential for achieving the desired properties in a polymer. For example, a polymer used for packaging needs a high PDI to provide good barrier properties, whereas a polymer used for fibers needs a lower PDI for strength and durability.

Examples of PDI Applications

Polyethylene (PE) for grocery bags typically has a PDI between 3 and 10, indicating a wide distribution of chain lengths. This allows for flexibility and tear resistance.

Polypropylene (PP) used in medical applications may have a PDI close to 1, meaning a narrower distribution of chain lengths for better biocompatibility and strength.

Understanding the polydispersity index is a crucial step in controlling and optimizing the properties of polymers. So next time you see a plastic bag or a bottle, remember that the PDI of the polymer plays a significant role in its performance.

FAQs

What is the significance of PDI in polymer characterization?

The PDI is a crucial parameter for characterizing polymers as it gives insights into the distribution of chain lengths within a sample. This information directly influences various properties such as strength, viscosity, and solubility, making it essential for controlling the performance of polymer materials.

How does PDI affect the mechanical properties of polymers?

A polymer with a narrow PDI (closer to 1) tends to exhibit higher strength and rigidity due to a more uniform chain length distribution, leading to stronger intermolecular forces. Conversely, polymers with a wider PDI (higher than 1) can have lower strength and more flexibility because of the presence of shorter chains.

Can you provide examples of polymer applications where PDI plays a crucial role?

Yes, absolutely. For instance, in polyethylene used for packaging, a higher PDI is desired to provide flexibility and tear resistance. On the other hand, polyethylene used for medical applications needs a lower PDI to ensure biocompatibility and strength. Similarly, polypropylene with a low PDI is preferred for fibers as it contributes to its strength and durability.

What are some techniques for controlling PDI during polymer synthesis?

Several techniques can be employed to control PDI during polymer synthesis. These include:

Controlling polymerization conditions: Careful control of temperature, monomer concentration, and catalyst type can significantly impact PDI.

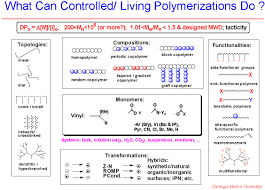

Using controlled polymerization techniques: Methods like atom transfer radical polymerization (ATRP) and ring-opening polymerization (ROP) allow for precise control over chain length and PDI.

Post-polymerization treatments: Techniques like fractionation and blending can be used to adjust PDI after polymerization.

How does PDI affect the processing of polymers?

The PDI can influence the processing of polymers, especially their melt viscosity. Polymers with a higher PDI tend to have higher melt viscosities, making them more difficult to process and requiring higher temperatures and pressures. This can impact extrusion, molding, and other processing steps.

Can you elaborate on the relationship between PDI and viscosity?

Generally, polymers with a higher PDI exhibit higher viscosities. This is because the presence of longer chains leads to increased entanglement and friction between molecules, making the polymer more resistant to flow.

What is the ideal PDI for a given application?

The ideal PDI depends on the specific application and desired properties. For example, a polymer for high-strength applications might require a low PDI, while a polymer for flexibility and elasticity might benefit from a higher PDI.

Are there any resources for further learning about PDI and polymer characterization?

Absolutely! There are many valuable resources available for learning more about PDI and polymer characterization, including:

Books: “Polymer Science and Technology” by Joel R. Fried, “Principles of Polymer Chemistry” by Paul J. Flory, “Polymer Characterization” by Hans-Joachim Cantow

Online resources: The American Chemical Society (ACS) website, Polymer Science & Technology Web (PST Web), The National Institute of Standards and Technology (NIST) Polymer Database

Scientific journals: “Macromolecules,” “Polymer,” “Journal of Polymer Science.”

I hope this in-depth exploration of the polydispersity index has provided you with a better understanding of its importance in polymer characterization. Feel free to reach out with any further questions!

See more here: How To Calculate Pdi In Dls? | Calculation Of Polydispersity Index Of A Polymer

Polydispersity Index – an overview | ScienceDirect Topics

PDI of a polymer is calculated as the ratio of weight average by number average molecular weight. Information on PDI is required for improved selection of polymers for an application [26]. For monodisperse polymers (all chain of same length, ScienceDirect

Polydispersity Index: How Accurately Does It Measure the

It is well-known that both average molecular weight and molecular weight distribution are the two key characteristics that determine properties of polymers and ACS Publications

Poly Dispersity Index (PDI)

If the ‘number average molecular weight’ and ‘weight average molecular weight’ of a polymer are 40,000 and 60,000 respectively, then calculate the polydispersity index SimplyScience

2.2: Molecular Weight Determination – Chemistry LibreTexts

There are several ways to calculate molecular weight of polymers like number average of molecular weight, weight average of molecular weight, Z-average Chemistry LibreTexts

Polymer Molecular Weight Distribution and Definitions of MW

The polydispersity index is used as a measure of the broadness of a molecular weight distribution of a polymer, and is defined by: Polydispersity index = Mw Mn The larger the Agilent

DISPERSITY IN POLYMER SCIENCE – International Union of

Abstract: This recommendation defines just three terms, viz., (1) molar-mass dis-persity, relative-molecular-mass dispersity, or molecular-weight dispersity; (2) de-gree-of International Union of Pure and Applied Chemistry

Polydispersity index and molecular weight distributions of

A ratio of the molecular weight averages, known as the polydispersity index (heterogeneity ratio, dispersion ratio, nonuniformity coefficient), defined by the ScienceDirect

Polydispersity Index: How Accurately Does It Measure the

Polydispersity indices (PDIs) of the two polymers allow estimates of the standard deviations of polyene molecular weights and conjugation lengths, 63 giving N = ResearchGate

Dispersity in polymer science (IUPAC Recommendations 2009)

Abstract. This recommendation defines just three terms, viz., (1) molar-mass dispersity, relative-molecular-mass dispersity, or molecular-weight dispersity; (2) degree- De Gruyter

See more new information: charoenmotorcycles.com

Polydispersity Index

Polydispersity Index (Pdi)- Polymer Chemistry-Engineering Chemistry1 Notes- Cy6151/Animation Video

Polydispersity Of Polymers | Polymer Engineering

Introduction To Polymers – Lecture 4.5. – Polydispersity And Other Averages

Mse 201 S21 Lecture 29 – Module 1 – Polymer Molecular Weight

Problem Solving – Polymer

Polymer Chemistry|Polydispersity Index|Mark Kuhn Houwink Equation|Viscosity Avg Molar Mass Csir-Net

Polymers – Number And Weight Average Molecular Weight, Distribution, Polydispersity – Part 1

1.2 Average Molecular Weights \U0026 Dispersity (Polydispersity Index)

Link to this article: calculation of polydispersity index of a polymer.

See more articles in the same category here: https://charoenmotorcycles.com/how